Hydraulic tools & hydraulic equipment play a crucial role in modern industries by delivering unmatched power, precision, and efficiency. From construction sites and manufacturing plants to automotive workshops and aerospace facilities, hydraulic systems provide the force needed to lift, press, cut, bend, and torque with ease. These tools and equipment operate using pressurized fluid, enabling heavy-duty performance that traditional mechanical or electric tools often can’t match.

In today’s fast-paced industrial environment, understanding how hydraulic tools & hydraulic equipment work—and selecting the right ones for your needs—can significantly boost productivity and safety. This comprehensive guide explores the full spectrum of hydraulic tools and equipment, highlighting their categories, applications, key components, selection criteria, maintenance tips, and emerging innovations.

Understanding Hydraulic Tools & Hydraulic Equipment

To fully grasp the power and versatility of hydraulic tools & hydraulic equipment, it’s important to understand what they are, how they function, and how they differ from each other. These devices are at the heart of many industrial operations where high-force output and precise control are essential.

What Are Hydraulic Tools?

Hydraulic tools are handheld or portable devices that use hydraulic power to perform specific mechanical tasks. These tools rely on fluid pressure generated by a hydraulic pump or cylinder to operate. They are commonly used for tasks such as lifting, cutting, pressing, bending, crimping, and tightening.

Examples include:

-

Hydraulic jacks for lifting heavy vehicles

-

Hydraulic torque wrenches for controlled bolt tightening

-

Hydraulic crimping tools for cable terminations

Hydraulic tools are valued for their:

-

High force-to-weight ratio

-

Smooth and controlled motion

-

Reliability under demanding conditions

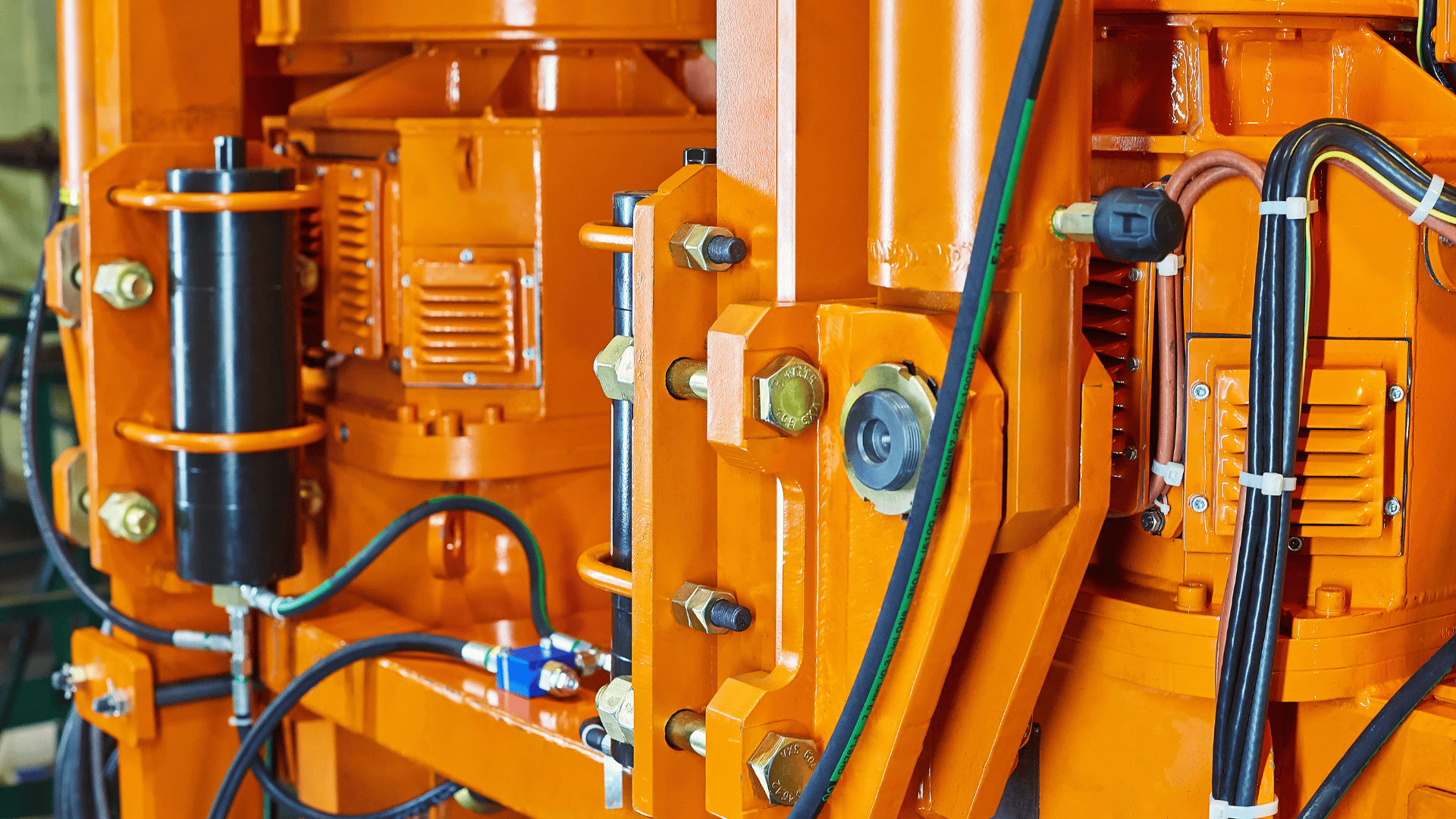

What Is Hydraulic Equipment?

Hydraulic equipment refers to larger systems or assemblies that use hydraulic power to operate machines or industrial processes. These are typically fixed or integrated into a system and consist of multiple components working together—such as hydraulic pumps, cylinders, motors, valves, and hoses.

Hydraulic equipment is used in:

-

Heavy machinery (excavators, forklifts, loaders)

-

Hydraulic presses in manufacturing

-

Industrial automation and robotics

-

Offshore drilling platforms

While hydraulic tools are often used by hand for maintenance and field tasks, hydraulic equipment forms the backbone of stationary or mobile machinery operations.

Key Differences Between Tools and Equipment

| Feature | Hydraulic Tools | Hydraulic Equipment |

|---|---|---|

| Portability | Handheld or portable | Fixed or large-scale systems |

| Power Source | Often uses portable pump or cylinder | Integrated with central power units |

| Applications | Service, maintenance, light construction | Heavy industry, automation, continuous operation |

| Components | Single-unit operation | Multiple interconnected components |

| Examples | Jack, wrench, crimper | Power unit, press system, actuator setup |

Manual vs. Powered Hydraulic Tools

Hydraulic tools can be manually operated (with hand or foot pumps) or powered using electric or pneumatic sources. Manual tools are more portable and ideal for fieldwork, while powered tools are used in environments that require higher output or repetitive tasks.

Stationary vs. Portable Hydraulic Equipment

Some hydraulic equipment is designed to be stationary, such as presses and industrial hydraulic power units, while others are mobile and integrated into vehicles or equipment like cranes and excavators. The selection depends on the application’s scale and mobility requirements.

HYDRAULIC BASICS

HYDRAULIC BASICS  HYDRAULIC COMPONENTS

HYDRAULIC COMPONENTS  HYDRAULIC SYSTEM

HYDRAULIC SYSTEM  HYDRAULIC SYMBOLS

HYDRAULIC SYMBOLS  HYDRAULIC STANDARDS

HYDRAULIC STANDARDS  HYDRAULIC CALCULATORS

HYDRAULIC CALCULATORS  HYDRAULIC TOOLS

HYDRAULIC TOOLS  BUYER’S GUIDES

BUYER’S GUIDES