How Does a Hydraulic System Work?

A hydraulic system works by using pressurized fluid to transmit power and perform mechanical tasks such as lifting, pressing, rotating, or moving loads. It operates based on Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

⚙️ Step-by-Step Process of How a Hydraulic System Works

1. Fluid Reservoir

-

The system begins with a reservoir that stores hydraulic fluid (usually oil).

-

This fluid is the medium used to transfer energy throughout the system.

2. Hydraulic Pump

-

A hydraulic pump (driven by an electric motor or engine) draws fluid from the reservoir.

-

It converts mechanical energy into hydraulic energy by pressurizing the fluid.

3. Control Valves

-

Directional control valves guide the pressurized fluid to specific parts of the system.

-

Pressure valves protect the system from overload.

-

Flow control valves adjust speed and force.

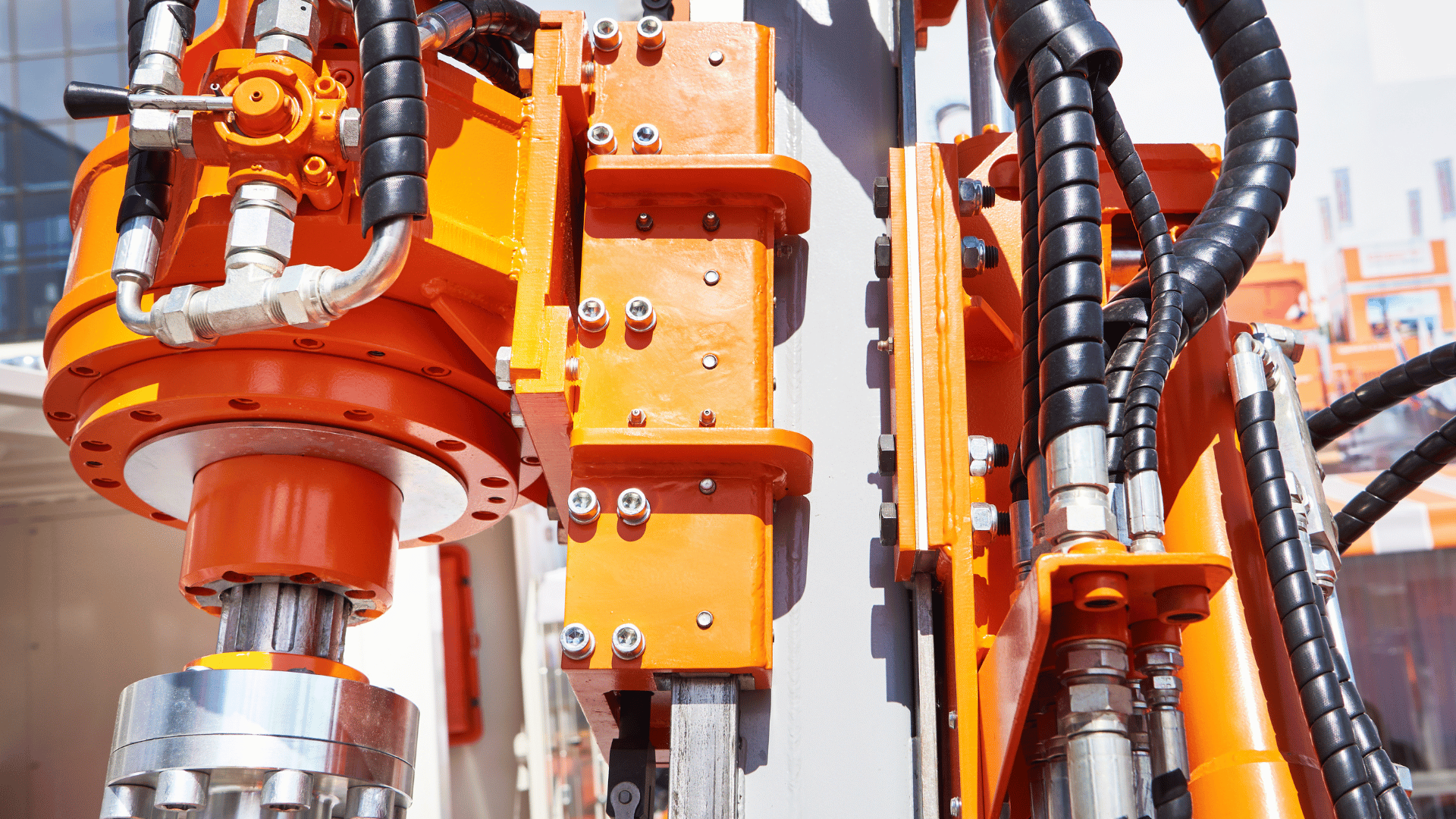

4. Actuators (Cylinders or Motors)

-

Pressurized fluid enters hydraulic cylinders (for linear motion) or hydraulic motors (for rotary motion).

-

The fluid force pushes a piston or turns a shaft, producing mechanical movement.

5. Return Line

-

After powering the actuator, the fluid flows through return lines back to the reservoir.

-

It may pass through a filter to remove contaminants before reuse.

🔁 Closed-Loop of Energy Transfer

[ Reservoir ] → [ Pump ] → [ Valves ] → [ Actuator ] → [ Return ] → [ Reservoir ]

💡 Key Concepts Behind the Operation

-

Incompressible Fluid: Since hydraulic oil doesn’t compress, it can transmit force efficiently and instantly.

-

Force Multiplication: A small force on a small piston can generate a large force on a larger piston (based on surface area ratio).

-

Precise Control: Adjusting valve positions allows smooth control over speed, direction, and power.

📊 Real-Life Example: Hydraulic Lift

-

Operator activates control valve.

-

Pump pushes fluid into lift cylinder.

-

Fluid pressure raises the platform.

-

Releasing the valve returns fluid to the tank, and the platform lowers.

✅ Summary: Why It Works So Well

-

Transfers large forces with minimal energy loss

-

Offers fine-tuned motion control

-

Scales easily for industrial or mobile applications

A hydraulic system transforms fluid pressure into powerful, controlled motion—essential for construction, manufacturing, aviation, and more.

HYDRAULIC BASICS

HYDRAULIC BASICS  HYDRAULIC COMPONENTS

HYDRAULIC COMPONENTS  HYDRAULIC SYSTEM

HYDRAULIC SYSTEM  HYDRAULIC SYMBOLS

HYDRAULIC SYMBOLS  HYDRAULIC STANDARDS

HYDRAULIC STANDARDS  HYDRAULIC CALCULATORS

HYDRAULIC CALCULATORS  HYDRAULIC TOOLS

HYDRAULIC TOOLS  BUYER’S GUIDES

BUYER’S GUIDES