HYDRAULIC BASICS

Hydraulic Basics and Principles: An Introduction to Fluid Power Systems

Hydraulics play a vital role in countless industries, powering everything from heavy construction machinery to precision aerospace components. Understanding hydraulic basics and principles is essential for engineers, technicians, students, and professionals who work with or design systems driven by fluid power. We provides a comprehensive introduction to hydraulic basics as hydraulic systems, their working principles, core components, and practical applications.

What Are Hydraulics?

Hydraulics is the branch of science and engineering concerned with the mechanical properties and use of liquids. In practical terms, hydraulics involves the transmission of force and motion through the controlled flow of pressurized fluid. It forms the foundation of many mechanical systems in industrial, mobile, and aerospace sectors.

Unlike pneumatics, which use compressed air, hydraulic systems use incompressible liquids—typically hydraulic oil—to transfer energy efficiently and precisely.

Core Principles of Hydraulics

Hydraulic systems function based on several fundamental scientific principles:

1. Pascal’s Law

Pascal’s Law states that when pressure is applied to a confined fluid, the pressure is transmitted equally and undiminished in all directions. This principle allows a small force applied at one point to be transformed into a much larger force at another point.

Formula:

This principle is the basis for lifting heavy loads with relatively low input force.

2. Pressure, Flow, and Force

- Pressure (P) is the force per unit area (measured in bar or psi).

- Flow rate (Q) determines how fast fluid is delivered (liters per minute, L/min).

- Force (F) is generated by applying pressure over a surface area.

A proper understanding of how these variables interact is crucial to hydraulic circuit design.

3. Energy Conservation

Energy within a hydraulic system is never lost; it is transformed between potential, kinetic, and thermal forms. Engineers design hydraulic circuits to maximize efficiency and minimize energy losses.

Basic Components of a Hydraulic System

Hydraulic systems rely on several core components that work together to transfer energy:

1. Hydraulic Fluid

Acts as the medium for power transfer, lubricates moving parts, removes heat, and helps seal gaps within components.

2. Reservoir (Tank)

Stores the hydraulic fluid and provides space for heat dissipation and air separation.

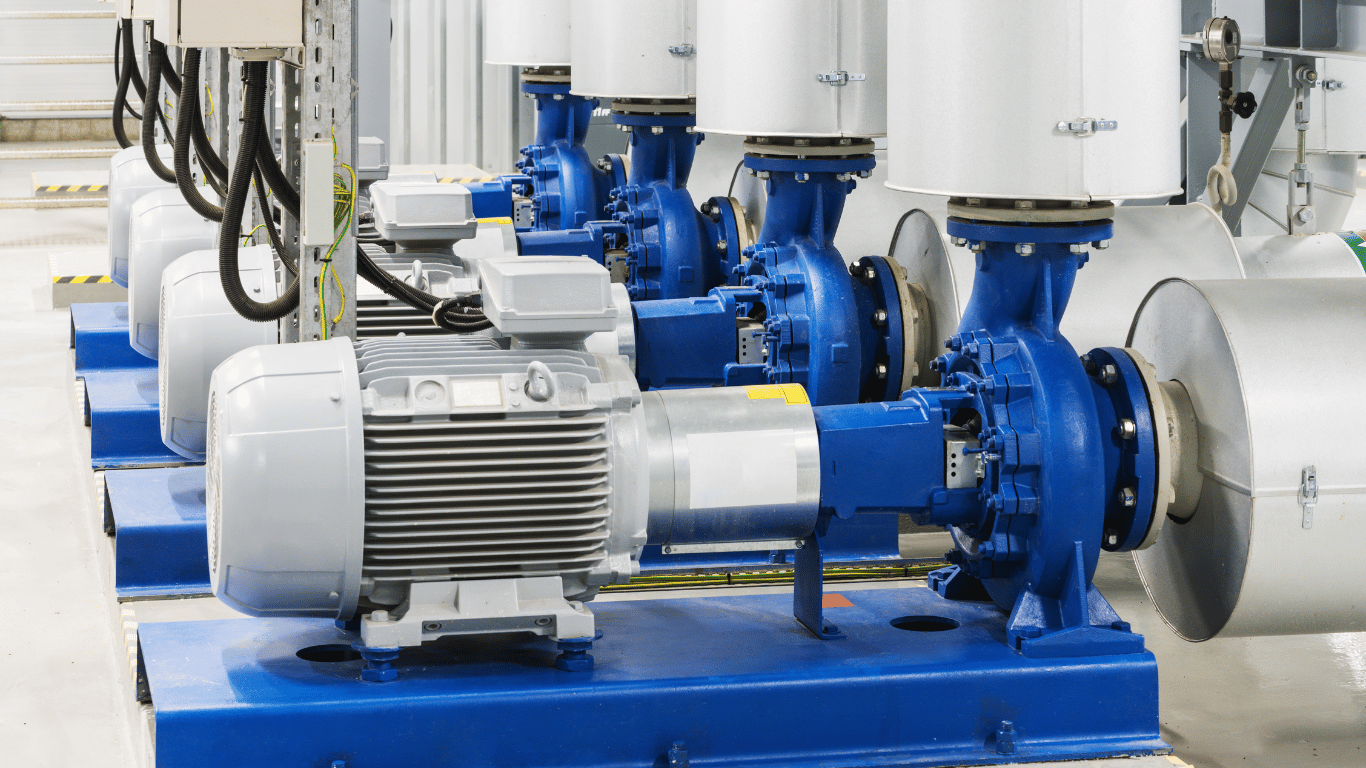

3. Hydraulic Pump

Converts mechanical energy into hydraulic energy by pressurizing fluid and pushing it into the system.

4. Valves

Control fluid direction, pressure, and flow. Types include:

- Directional control valves

- Pressure relief valves

- Flow control valves

5. Actuators (Cylinders and Motors)

Convert hydraulic energy back into mechanical energy. Cylinders produce linear motion, while motors produce rotary motion.

6. Filters and Lines

Maintain cleanliness by removing contaminants from the fluid and transport fluid between components.

How a Hydraulic System Works

Hydraulic systems operate in a closed-loop or open-loop format. Here is a basic step-by-step overview of how fluid moves through a hydraulic system:

- Fluid is drawn from the reservoir to the pump.

- Pump pressurizes the fluid and sends it into the system.

- Valves regulate direction, pressure, and flow.

- Actuators perform work, like lifting or rotating.

- Fluid returns to the reservoir for reuse.

The system continuously cycles fluid to deliver consistent and controllable force and motion.

Types of Hydraulic Circuits

- Open-loop systems: Fluid flows from a reservoir to the actuator and returns without recirculating through the pump.

- Closed-loop systems: Fluid continuously circulates between the pump and actuator without returning to the tank until needed.

Each type serves different needs based on speed control, efficiency, and application.

Hydraulic Symbols and Schematics

Understanding hydraulic symbols is crucial for interpreting and designing system schematics. Common symbols include:

- Pumps: A circle with an arrow

- Reservoirs: Open or closed rectangles

- Cylinders: Hollow rectangles with a rod

For a full guide, refer to our dedicated [Hydraulic Symbols & Diagrams] page.

Applications of Hydraulic Systems

Hydraulic systems are used across industries for their reliability and power density:

- Construction: Excavators, loaders, cranes

- Manufacturing: Presses, molding machines

- Agriculture: Tractors, plows, combines

- Aerospace: Flight controls, landing gear

- Marine: Winches, rudder systems

Benefits of Hydraulic Systems

- High power-to-weight ratio

- Smooth, precise control

- Robust operation in extreme conditions

- Easy to scale for different applications

Challenges and Safety Considerations

- Hydraulic leaks and contamination

- System overheating

- Risk of fluid injection injuries

- Pressure management and emergency shutdowns

Safety practices, such as proper maintenance and protective equipment, are critical.

Conclusion

Mastering hydraulic basics and principles lays the groundwork for understanding more advanced systems and applications. Whether you’re an engineer designing circuits or a technician troubleshooting faults, a solid grasp of hydraulic fundamentals ensures better decisions and safer operations.

Explore more topics on Hydraulic Insight:

- [Hydraulic Components Overview]

- [Hydraulic Tools & Equipment]

- [Hydraulic Troubleshooting Guide]

Hydraulic systems are powerful, precise, and essential. Let this be your starting point to explore the entire world of fluid power.

HYDRAULIC BASICS

HYDRAULIC BASICS  HYDRAULIC COMPONENTS

HYDRAULIC COMPONENTS  HYDRAULIC SYSTEM

HYDRAULIC SYSTEM  HYDRAULIC SYMBOLS

HYDRAULIC SYMBOLS  HYDRAULIC STANDARDS

HYDRAULIC STANDARDS  HYDRAULIC CALCULATORS

HYDRAULIC CALCULATORS  HYDRAULIC TOOLS

HYDRAULIC TOOLS  BUYER’S GUIDES

BUYER’S GUIDES