Introduction to Hydraulic Components

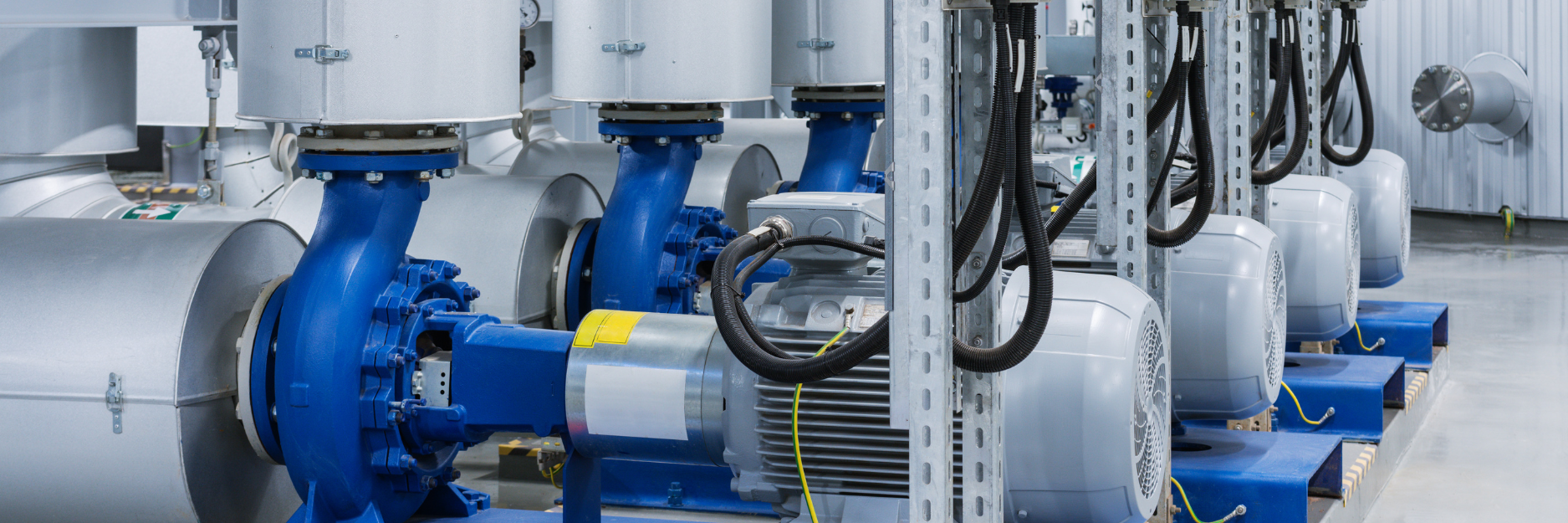

Hydraulic components form the backbone of countless industrial and mobile machinery systems, enabling precise control of movement and force through the transmission of pressurized fluid. These components are essential to the operation of hydraulic systems used in manufacturing, construction, aerospace, automotive, and agricultural applications. Whether it’s lifting heavy loads, steering vehicles, or operating automated equipment, hydraulic components ensure that power is delivered efficiently and reliably.

At its core, a hydraulic system uses incompressible fluid—usually oil—to transfer energy from a power source (such as a hydraulic pump) to an output device (such as a hydraulic cylinder or motor). Along the way, a variety of hydraulic components work together to control the direction, pressure, and flow of this fluid. Each component in the system plays a specific role, from generating and regulating power to converting it into mechanical work.

The importance of understanding hydraulic components cannot be overstated. Proper selection, integration, and maintenance of these parts are critical to system performance, safety, and longevity. In industrial environments where uptime and efficiency are key, knowing how each component functions and interacts with others is vital for both engineers and operators.

This article provides a comprehensive overview of hydraulic components, diving into their classifications, functions, design considerations, and applications. Whether you are a technician, an engineer, or simply someone interested in the field of hydraulics, this guide will equip you with a solid foundation in how hydraulic systems operate through their essential components.

HYDRAULIC BASICS

HYDRAULIC BASICS  HYDRAULIC COMPONENTS

HYDRAULIC COMPONENTS  HYDRAULIC SYSTEM

HYDRAULIC SYSTEM  HYDRAULIC SYMBOLS

HYDRAULIC SYMBOLS  HYDRAULIC STANDARDS

HYDRAULIC STANDARDS  HYDRAULIC CALCULATORS

HYDRAULIC CALCULATORS  HYDRAULIC TOOLS

HYDRAULIC TOOLS  BUYER’S GUIDES

BUYER’S GUIDES